BACKGROUND

Britannia Industries Limited (Britannia), a well-recognised food product industry, has been a market leader for over a century. With 90 plants and manufacturing units across India and abroad, Britannia is renowned for its biscuits, breads, cakes and dairy products.

Their unwavering commitment to sustainability has spurred the company to seek alternatives for complex, non-recyclable packaging solutions.

Britannia aims to develop a fully recyclable mono-material solution by replacing complex non-recyclable packaging. This initiative is intended to help recycle waste equivalent to the amount of packaging used across their portfolio, allowing them to achieve material neutrality.

In close collaboration, Borouge and Britannia sought to develop a fully recyclable mono-material solution without compromising the performance and properties of the packaging.

Britannia operates with fastest packaging lines; a key requirement was the need for stiffness and sealing performance while transitioning to a mono-material film structure.

SOLUTION

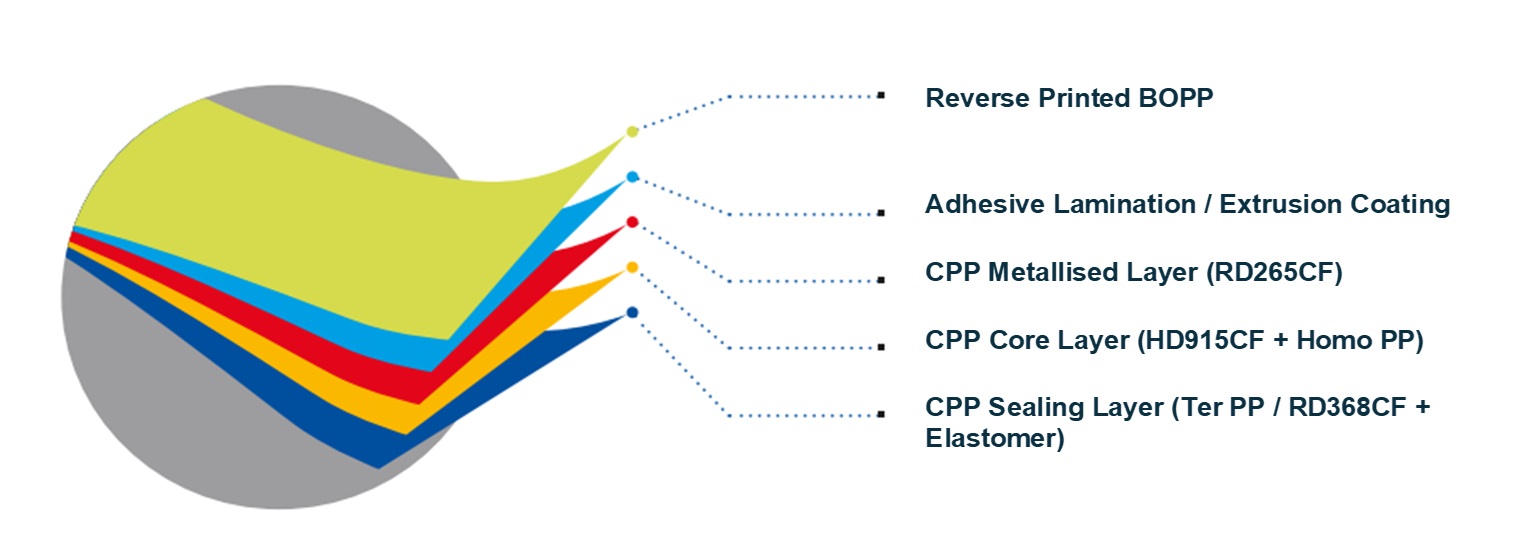

Using Borouge’s premium polypropylene - RD265CF that offers outstanding metal adhesion, and HD915CF, a high crystalline homopolymer PP based on Borstar® Nucleation Technology that offers superior stiffness, the team developed a customised multi-layered cast polypropylene (CPP) film that met Britannia’s requirements for stiffness, packaging speed and improved processing capabilities.

Key benefits include:

- Higher packaging speed

- Enhanced stiffness

- Designed for recyclability

With a harmonised 3-layer mono-material film, Britannia stands to benefit from the ability to run the laminate on all generations of machines, higher line speeds, reduction in the number of laminate structures and improve the full recyclability of their packaging materials.

"We are thrilled with the results of our collaboration with Borouge. The transition to a mono-material film structure not only enhances our packaging speed and stiffness but also aligns with our commitment to sustainability. This innovative solution reflects our dedication to creating recyclable packaging materials while maintaining superior product integrity and shelf life. Together, we are setting new standards in the packaging industry and advancing towards a circular economy." - Mr. Santosh Kumar Panda, Sr. Group Manager - Packaging Development, Britannia Industries Ltd.

This success story exemplifies both companies’ commitment towards collaboration and innovation to create sustainable packaging solutions.